The Phone I Couldn’t Fix

A few years ago, my phone’s battery started dying within hours. It was a great device — fast, reliable, and expensive — but the repair shop said it wasn’t “worth fixing.” The manufacturer had glued the battery in place, making replacement nearly impossible. My only “solution” was to buy a new model.

That moment stuck with me. Why should a $700 device become useless just because of a battery? Why do companies make products harder to repair instead of easier? This personal experience opened my eyes to a bigger issue — repairability in electronics. It’s not just about convenience; it’s about sustainability, affordability, and consumer rights. When repairability is ignored, devices become disposable, and the cycle of waste continues.

This isn’t just my story — it’s the story of millions of consumers facing the same issue. As devices become more complex, repairability in electronics has turned into a global concern. It’s not only about convenience or cost — it’s about sustainability. Every gadget we throw away adds to the world’s growing mountain of e-waste. The solution lies in designing technology that’s built to last, repair, and reuse.

Table of Contents

What Is Repairability in Electronics?

Repairability is the measure of how easy it is to fix, upgrade, or replace parts in a device.

As of mid-2025, Europe is taking meaningful steps toward enforcing repairability in electronics. New ecodesign rules now require smartphones, tablets, and other devices sold in the EU to meet minimum standards of durability, energy efficiency, and ease of repair. Internal Market & SMEs Meanwhile, the Global E-Waste Monitor 2024 indicates that in 2022 alone, 62 million tonnes of electronic waste were generated worldwide — yet only about 22.3 % was formally recycled. E-Waste Monitor+1 The gap between waste produced and waste responsibly handled underscores the urgent need for devices designed to be repaired, not discarded.

Key factors include:

- Availability of spare parts

- Repair manuals and diagnostic tools

- Modular design (e.g., replaceable battery, screen, storage)

- Manufacturer support for third-party repairs

The Problem with Planned Obsolescence

Planned obsolescence refers to the deliberate practice by companies of designing and manufacturing products with purposely limited lifespans, ensuring that these items become outdated, non-functional, or unfashionable within a relatively short period of time after purchase. This strategy is often used to encourage consumers to replace products more frequently, thereby driving continuous sales and increased profits for the manufacturers.

Examples:

- Sealed batteries → can’t be replaced without special tools.

- Glued screens → crack once, whole phone is gone.

- Software obsolescence → no updates after 3 years, even if hardware is fine.

This practice is profitable for manufacturers but devastating for:

- Consumers → forced into expensive upgrades.

- Environment → millions of tons of electronics dumped.

💡 Personal Note: I once cracked a laptop hinge and was told repairs would cost more than a new device. Instead of throwing it out, I found a small independent shop that fixed it for $40. That’s when I realized: repair is possible, if companies allow it.

The Right to Repair Movement

The Right to Repair is a growing global movement that aims to give consumers and independent repair shops the tools, parts, and information they need to fix their own devices safely and affordably. At its core, it challenges manufacturers to design products with repairability in electronics as a standard — not an afterthought. This means allowing access to repair manuals, diagnostic software, and reasonably priced spare parts, empowering users to extend the lifespan of their gadgets. Beyond personal convenience, the Right to Repair also plays a vital role in reducing e-waste, cutting carbon emissions, and promoting a more sustainable technology ecosystem worldwide.

Europe

- EU requires manufacturers to provide spare parts for up to 10 years.

- Energy efficiency labels now include repairability scores.

United States

- States like New York passed Right to Repair laws in 2023.

- Resistance from tech giants remains strong.

Other Regions

- India exploring Right to Repair framework.

- Australia considering stronger consumer rights.

Case Studies: Repairability in Practice

1. Framework Laptop

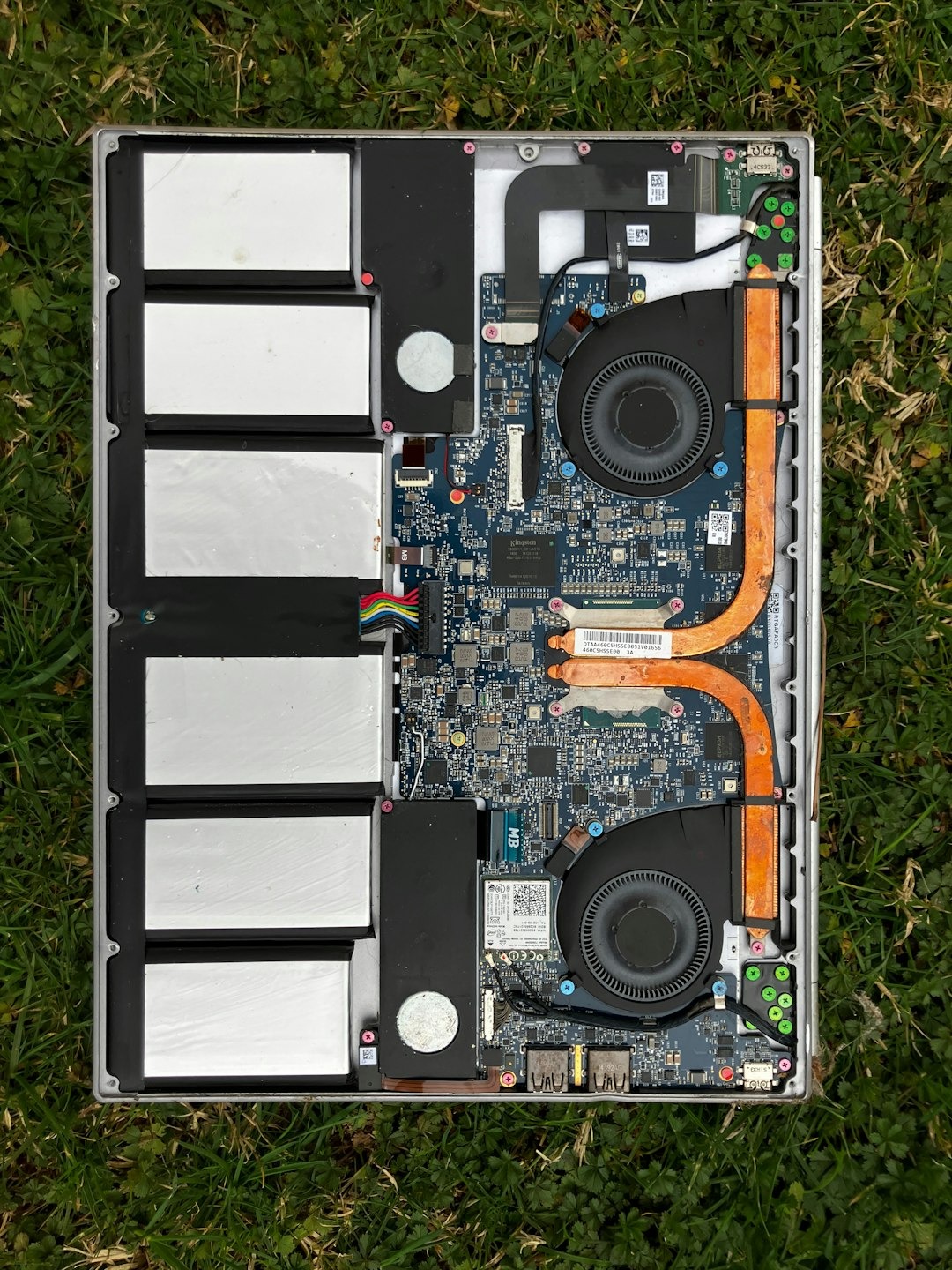

- Fully modular design.

- Every part labeled and replaceable.

- 10/10 iFixit score.

2. Fairphone

- Modular smartphone with replaceable battery, camera, and screen.

- Focus on fair minerals and labor.

3. Apple

- Historically unrepairable (sealed designs).

- Recently launched Self Service Repair program → but still limited.

4. iFixit

- Community-driven repair guides.

- Pushes transparency and DIY repair culture.

💡 Personal Note: I followed an iFixit guide to replace my own phone screen once. It was nerve-wracking, but finishing it gave me a sense of control — and saved me $200.

Environmental & Economic Benefits of Repairability

Environmental

- Repair extends device life, delaying landfill waste.

- Fewer new devices manufactured = reduced mining and emissions.

Economic

- Repair creates local jobs in small shops.

- Refurbishment industry growing globally.

- Consumers save by repairing instead of buying new.

Challenges to Repairability

- Corporate Resistance

- Companies profit from new sales.

- Fear of losing control over “authorized” repairs.

- Technical Complexity

- Waterproofing and miniaturization make designs harder to open.

- Consumer Awareness

- Many don’t know repair options exist.

How You Can Support Repairability

Here’s a practical checklist:

- Buy repairable products → Check iFixit scores.

- Support Right to Repair laws → Sign petitions, support legislation.

- Learn simple fixes → Replace your own battery or hard drive.

- Visit repair cafes → Community events where people fix devices together.

- Choose refurbished before new.

- Recycle responsibly when repair isn’t possible.

The Future of Repairability in Electronics

- Modular devices → Mainstream adoption by 2030.

- AI diagnostics → Apps that identify faults and guide repairs.

- Repair-as-a-service → Subscription models for device maintenance.

- Legislation expansion → Global adoption of Right to Repair.

Author’s Take

Repairability isn’t just about saving money — it’s about reclaiming power. Companies want us to upgrade endlessly, but repair is an act of resistance.

When I fixed my own laptop hinge, I realized how much unnecessary waste I had avoided. I believe the future belongs to devices we can open, understand, and keep alive for years.

Conclusion

Repairability in electronics is the backbone of sustainable technology. Without it, we’re trapped in a cycle of waste and endless upgrades. With it, we empower consumers, protect the environment, and create a fairer digital future.

🌱 Call to Action: Next time your device breaks, don’t ask “Which new model should I buy?” Ask: “Can I repair this?”